Chainmail gloves, aprons und boleros

Cleaning and care aprons

Products made of ring mesh must be cleaned immediately after use with warm water, approx. 50° C, with the addition of cleaning agents commonly used in the butchery and food industry, by vigorous brushing. Very good cleaning is also achieved if the gloves or aprons are washed in a normal and/or customary washing machine. After the product has dried, it must be sprayed with a disinfectant commonly used in the food industry (leave to act for a few minutes). After cleaning, store the products in a dry, cool and well-ventilated place. It’s important to ensure that only disinfectants commonly used in the food industry are used. Disinfectants with excessive chlorine and acid content can damage products.

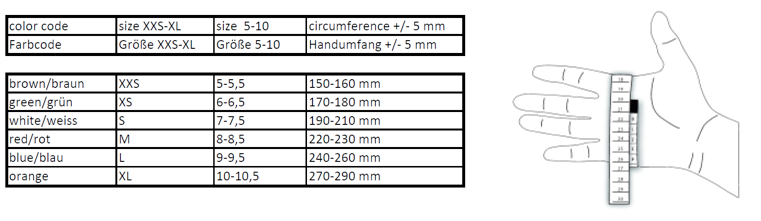

Left hand - right hand

Choice of RGH (hand measure)

Gloves should not be worn too tight, as this restricts flexibility and wearing properties. For a comfortable fit, 5mm can be added to the circumference. If a cotton glove or under glove is worn under the ring mesh glove, a further 3 mm circumference is added.

Weights/sizes: Boleros

Please refer to the information in the size chart on the product page

Weights/sizes: Aprons

Please refer to the information in the size chart on the product page

Repairs

Protective aprons and gloves may only be used in the form supplied by the manufacturer. Only in this form do the products comply with national and European requirements. Only faultless products may be used in the work. Necessary repairs may be carried out using original spare parts. A professional repair is only guaranteed in this case. With the original niroflex repair service, we help unbureaucratically and professionally with problems with CE-compliant products made of ring mesh.

Color Code

brown = XXS, green = XS, white = S, red = M, blue = L, orange = XL, olive = XXL

Sales partner at home and abroad

Internationale sales partner: Distribution

National = regional sales partner

MOQ

Available upon request

ISO certification

ISO 9001

Powered knives/saws

No – exception: easyfit can be used to a limited extent

Ring size aprons / boleros

When using extremely sharp knives, Ø 4.2 mm is recommended. Otherwise Ø 7.0 mm

Delivery time

Most products are available from stock. Orders from our standard range leave our shipping center on the same day.

Custom manufacture

Customization feasible for people and applications. We develop ideas and products together with our customers and create tailor-made solutions, application-oriented down to the smallest detail.

Cut resistant gloves

Care and cleaning

Washing and care instructions

Wash the cut resistant gloves with a normal wash cycle at no more than 85°C (185°F). A spin cycle will reduce the drying time. When using a dryer, do not exceed the max. temperature of 70°C (160°F) or 10 minutes’ drying time. The gloves must be stored in a dry place.

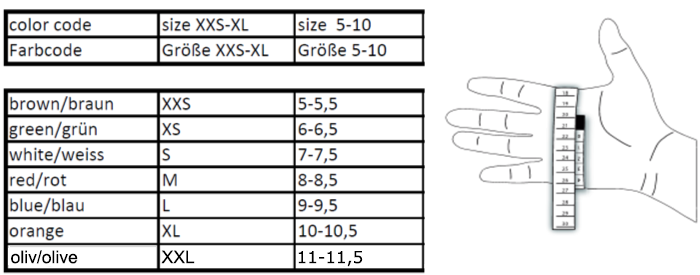

Left hand, right hand

Choice of RGH (measure hand)

What does cut protection mean?

niroflex cut resistant gloves offer a high resistance to cuts and abrasion, but do not protect against punctures. The gloves must not be used in the vicinity of power blades, knives, saws, or similar tools.

Skin tolerance

The gloves generally do not bother the skin and should not cause allergic reactions when a commercially available detergent is used

Wash cycles

Only faultless niroflex BlueCut gloves may be used during work. The buyer and/or users are responsible for the correct use of the gloves. The manufacturer and/or seller do not assume any liability or guarantee.

There is no guarantee that the specified performance levels will be guaranteed after more than 20 wash cycles.

Color coding

brown = XXS, green = XS, white = S, red = M, blue = L, orange = XL, olive = XXL

Sales partners domestic and abroad

Internationale sales partner: Distribution

National = regional sales partner

MOQ

10 pieces per size

Powered knives/saws

No

Disposal

Used gloves must be disposed of in accordance with the disposal regulations for pollution and the regulations of the local authority.

Unused gloves can be disposed of with household waste.

Delivery time

Most products are kept in stock.

Method for testing cut resistance

Coupe test (EN 388:2003) remains a part of EN 388:2016. As an additional cutting test, the test method from ISO 13997 was integrated into the current EN 388. This test is more informative than the previous Coupe test, as the force actually measured when cutting is given in newtons (N). The cut protection classes are classified by coding the letters A through F, with A (2 N) representing the lowest and F (30 N) the highest performance levels.

Application solutions

100 years of technical experience in connection with critical work areas is the basis for supporting our dealers and their customers in choosing the right product for their requirements. We are always available to answer your questions.

Allergic reactions

One allergic reaction caused by gloves is the reaction to nitrile proteins and/or additives used in the manufacture of gloves. While most allergies generally show mild symptoms, a very small percentage may lead to serious reactions.

Gloves with cuffs

We recommend a glove with a certain cuff length (approx. 40.5 cm) if protection up to the elbow is desired. Also suitable for pulling over armguards.

When and where should I wear cut-resistant gloves?

When using hand knives, wear the cut-resistant gloves on the hand holding the item being cut and on the hand holding the knife.

Are the gloves suitable for the food processing industry?

All of our gloves are suitable for use in food processing and/or food manufacturing.

What does DIN EN 388:2003 have to say?

The European standard DIN EN 388: 2003 describes the requirements, test methods, and markings required of protective gloves with regard to physical and mechanical loads when carrying out work. This standard applies together with the basic standard DIN EN 420. The mechanical risks and loads and their test methods are defined in DIN EN 388:2003 as follows: abrasion resistance; cut resistance; tear strength; puncture resistance.

What does abrasion resistance mean?

Abrasion resistance is determined as the number of cycles required until the surface of the glove is penetrated. Penetration occurs when the test specimen is worn to the point that a hole has appeared.

What does cut resistance mean?

The cut resistance value is based on the number of test cycles required to cut the test glove with a fixed load (5N) at a constant speed.

What does tear resistance mean?

Tear resistance is defined as the force which is required to tear a crack in a rectangular test specimen over half its length.

What does puncture resistance mean?

The piercing force is defined as the force that is required to puncture a test specimen attached to a holding device with the aid of a steel pin with specified dimensions. This should not be confused with perforation using thin tips or needles.

Labeling

The protective function against mechanical injuries is shown with a pictogram and five digits. These indicate the respective performance levels.

Test method EN 388: 2003

The previous cut protection test for cut protection gloves is carried out using the so-called coupe test. A rotating circular knife moves back and forth on the test item with a defined force (5N) and rotates in the opposite direction to the movement. The sharpness of the blade is measured using a reference tissue at the beginning of the test and at the end of the test. The wear on the blade can thus be determined and taken into account. The index value shows the number of cycles required to cut through the test specimen and the degree of wear on the blade used.

Test method EN 388:2016/ISO 13997

In the test procedure according to ISO 13997, the durability of the glove against a sharp-edged object is determined in the event of a single contact with greater force. To do this, a long straight blade is moved once over the test item. The minimum force to the cross-section of the test piece after 20 millimeters is determined. The result is given in newtons (N) which is then used to determine the cut protection class of the specimen.

DIN EN 511 protection against cold

The gloves certified under DIN EN 511 are intended to protect the wearer from both convection cold (penetrating cold) and contact cold (direct contact). The individual aspects are classified into different performance levels. The performance levels are indicated with a number from 1 to 4 next to the pictogram, with 4 describing the highest performance level.

DIN EN 407 protection against thermal risks

Protective gloves that are certified in accordance with the DIN EN 407 standard protect the wearer, for example, from contact and/or radiant heat. The protective gloves are classified and tested according to the following criteria: Protection against ignition; Protection against contact heat; Protection against convection heat.